Methane, a potent greenhouse gas, is naturally produced in many crucial industries such as agriculture and wastewater treatment. What if we could grab that gas before it goes into the atmosphere, and make something useful out of it?

Mango Materials, a California-based biomanufacturing company, has invented a way to do just that. Using a special mixture of methane-eating microorganisms, Mango’s process converts methane into a biodegradable polymer called polyhydroxyalkanoate (PHA), which can be compounded into 100% biodegradable polyester pellets to form durable goods, fabrics, and flexible films that have all the convenient properties of plastics but can have a much lighter environmental footprint.

Like all biomanufacturing technologies, it took time for Mango to move from a lab-scale concept to an efficient commercial process. Helping academic and industry groups bridge this difficult transition is the specialty of scientists at the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), part of Lawrence Berkeley National Laboratory (Berkeley Lab) and funded by the Bioenergy Technologies Office at the U.S. Department of Energy.

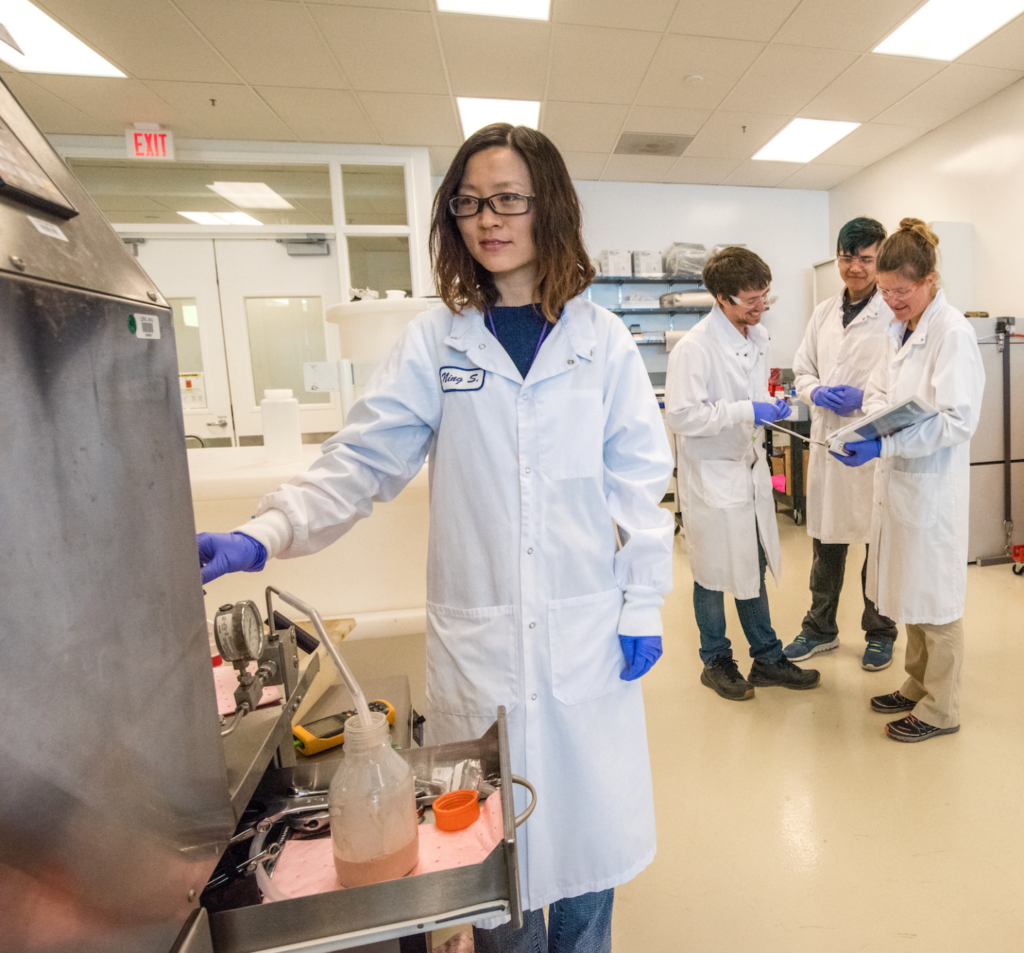

Mango set their sights on maximizing the amount and purity of PHA they could recover from inside their microbes; for this, they started working with an ABPDU team led by Ning Sun, a staff scientist in Biological Systems and Engineering (BSE). During this time, they collaborated to test out industrial-scale relevant equipment so the scientists could determine what worked before investing in their own pilot scale systems.