Lygos and Lawrence Berkeley National Lab’s Advanced Biofuels Process Demonstration Unit have collaborated to scale up production of biomass-derived specialty chemical.

Lygos and Lawrence Berkeley National Lab’s Advanced Biofuels Process Demonstration Unit have collaborated to scale up production of biomass-derived specialty chemical.

Lygos, Inc., announced today that it has successfully achieved pilot scale production of malonic acid from sugar. Lygos’ novel manufacturing technology decreases CO2 emissions, eliminates toxic inputs and could replace the existing petroleum production process for malonic acid at lower cost and less energy.

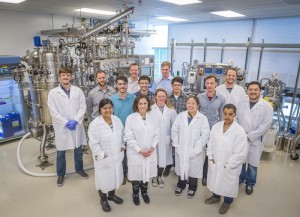

ABPDU and Lygos team members in the ABPDU facility. From left to right, Back Row: Stephen Hubbard (ABPDU), Eric Steen (Lygos), David Melis (Lygos), Todd Pray (ABPDU), Scott Akers (ABPDU). Middle: Eric Gates (Lygos), Clayton McSpadden (Lygos), Will Holtz (Lygos), Jeffrey Dietrich (Lygos CTO), Rogelio Denegri III (ABPDU). Front: Deepti Tanjore (ABPDU), Azadeh Alikhani (Lygos), Kristy Hawkins (Lygos), Tina Mahatdejkul-Meadows (Lygos), Firehiwot Tachea (ABPDU). (Credit: Roy Kaltschmidt/Berkeley Lab)

Malonic acid is currently a high-value specialty chemical useful for production of a variety of pharmaceuticals, flavors, fragrances, and specialty materials. The petrochemical process to produce malonic acid requires chloroacetic acid and sodium cyanide, and is both costly and environmentally hazardous. Lygos’ fermentation technology is environmentally benign, scalable, and enables production of malonic acid at a lower cost than the current petrochemical manufacturing process.

A versatile compound, malonic acid was identified by the U.S. Department of Energy as one of the “Top 30 Value Added Chemicals” to be produced from biomass-derived sugar, instead of petroleum. Lygos has identified over $1 billion in derivative specialty and commodity chemicals that can be accessed from malonic acid, and developing its fermentation technology is key to enabling these opportunities.

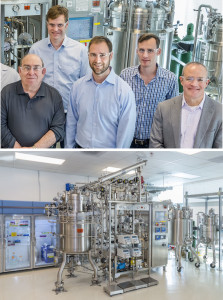

Top: Lygos co-founders with Todd Pray, head of the ABPDU. From left: Leonard Katz, Pray, Eric Steen, Jeffrey Dietrich, and Jay Keasling. Bottom: Fermenter used in the scale-up of malonic acid. (Credit: Roy Kaltschmidt/Berkeley Lab)

“This is an exciting achievement for our team – it’s the first time malonic acid has been produced in meaningful quantities from renewable materials instead of petroleum,” said Dr. Eric Steen, CEO of Lygos. “The process metrics we observed at lab scale were successfully transitioned to pilot scale. With this manufacturing run, we are able to provide samples of high quality malonic acid to customers and partners. As we move forward with commercialization, we’re seeking additional partners to accelerate larger scale manufacturing and unlock new product applications.”

The scale-up was performed at Berkeley Lab’s Advanced Biofuels Process Demonstration Unit (ABPDU), which is located in Emeryville, CA. “Lygos’ process transfer went smoothly and proved to be robust. We look forward to further scale-up activities with our partner,” said Todd Pray, head of ABPDU.

The successful achievement of pilot scale manufacturing was completed in the research phase of a program funded in part by the Bioenergy Technologies Office, in the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE).

For more information about Lygos, go here or contact Eric J. Steen, PhD, CEO of Lygos, Inc.

# # #

Lygos is an industrial biotechnology company developing fermentation processes for cost effective production of bio-chemicals. Learn more at www.lygos.com.

The Advanced Biofuels Process Demonstration Unit (ABPDU) is a state-of-the-art facility at Lawrence Berkeley National Laboratory available to industry, national laboratories, and academic institutions for the demonstration of biomass deconstruction and advanced biofuel/bio-based chemical production processes, The facility was built and is operated with funds from the BioEnergy Technologies Office within the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy, and was also funded by the American Recovery and Reinvestment Act. Visit www.abpdu.lbl.gov for more information.

Lawrence Berkeley National Laboratory addresses the world’s most urgent scientific challenges by advancing sustainable energy, protecting human health, creating new materials, and revealing the origin and fate of the universe. Founded in 1931, Berkeley Lab’s scientific expertise has been recognized with 13 Nobel prizes. The University of California manages Berkeley Lab for the U.S. Department of Energy’s Office of Science. For more, visit www.lbl.gov.