Biomanufacturing is a type of production that harnesses the molecular machinery in microbes, cells, and plants to produce a variety of valuable compounds. This approach enables efficient biomanufacturing of products that are traditionally made in limited quantities or using environmentally unfriendly practices, and to make entirely new molecules with exciting properties, such as innovative fuels, chemicals, foods, medicines, materials, and even rocket fuel. U.S. biomanufacturing is currently estimated to add more than $210 billion to the economy every year, and this number will likely increase as more bioproducts are developed.

Several Biosciences Area scientists have made contributions to the field of biomanufacturing.

Expert Interview: Blake Simmons

Blake Simmons, director of the Biological Systems and Engineering Division (BSE), speaks on how biomanufacturing supports the U.S. goal of increased domestic production. Read a transcript of this interview.

A team led by synthetic biology pioneer Jay Keasling, a senior faculty scientist in the BSE division, developed a yeast strain that produces the plant-derived anti-cancer compound vinblastine, a breakthrough that will allow drug makers to generate large quantities of the compound using an easily cultured microbe. Keasling and his colleagues have applied their approach to making a diverse range of other products, including energy-dense fuel molecules for aviation and rocketry and polymers for infinitely recyclable plastic.

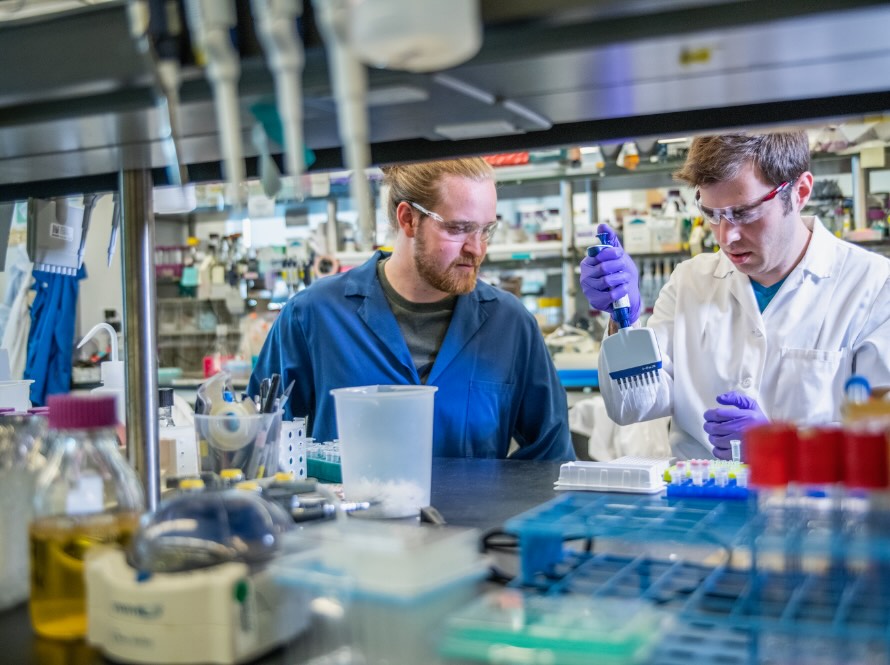

Researchers at the Joint Bioenergy Institute (JBEI) are developing techniques to convert lignin into biofuels and bioproducts. The energy stored within these plant tissues often goes to waste because it’s difficult to break the complex polymers into simpler molecules. JBEI scientists are using targeted chemical pretreatments and the capabilities of bacteria and fungi that can digest these processed biomass tissues in nature. Others are working to engineer culturable microbial strains that can metabolize these sugars and intermediates in order to make products.

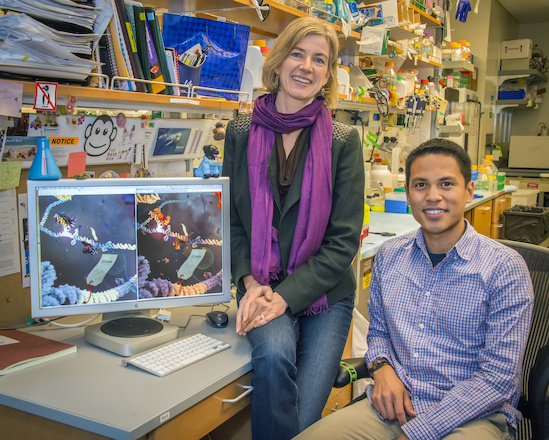

In 2008, Jennifer Doudna, a faculty scientist in the Molecular Biophysics and Integrated Bioimaging (MBIB) division, conducted foundational research into the naturally occurring bacterial immune defense system that she and colleagues later modified to invent the Nobel Prize-winning CRISPR-Cas gene editing platform. Today, CRISPR-Cas technologies provide a streamlined toolkit that scientists can use to modify genes in any organism, ushering in a new era of biological research and enabling development of revolutionary bio-based products and medical treatments. Doudna is currently using advanced CRISPR tools to develop methods for enhancing lignin breakdown using gene edited microbial communities at JBEI, where she is a scientific lead in the Biological Lignin Depolymerization group.

Established in 2009, the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU) has worked with more than 79 industry partners to launch a diverse range of products including plastics made from methane waste gas, animal-free collagen for supplements and beauty products, and outdoor gear made from algae. The ABPDU is one of the only facilities in the world that offers access to the technical support and equipment necessary to bridge the gap between pilot scale and industrial scale. Berkeley Lab is also a member of the Agile BioFoundry, a consortium of national laboratories that focuses on accelerating bioproduct development from initial host engineering to scale up, and engages in partnerships that result in technology transfer to industry.

Scientists at the ABPDU and JBEI are leaders in the field of technoeconomic analysis (TEA) and lifecycle assessment (LCA) – approaches that paint a picture of the economic and environmental impacts that an early-stage technology could have in the future. Collaboration with our TEA and LCA experts helps innovators address potential issues relating to supply chains and material costs, distribution, sustainability, and price competitiveness while their product is still in development.