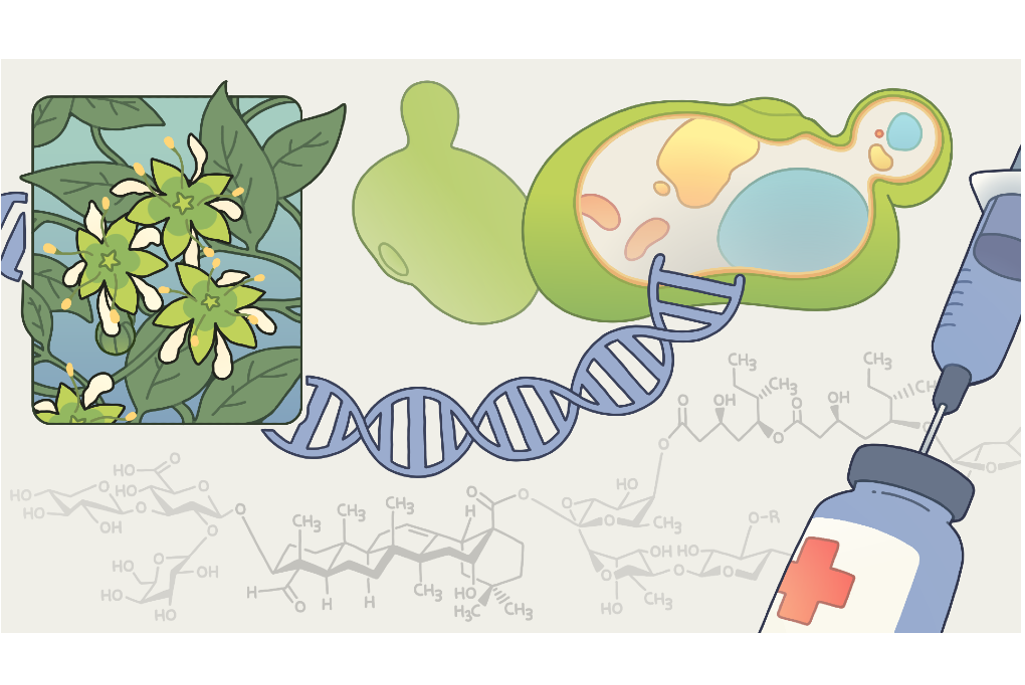

Biosciences Area Senior Faculty Researcher Jay Keasling and his research team have spent the past few decades engineering yeast to be tiny factories that more efficiently produce molecules that are typically found in small supply in nature. Now, they have modified yeast to make the adjuvant QS-21, an important additive to vaccines that stimulates the immune response, making vaccines more effective. This process, developed in collaboration with an international team of scientists, was recently published in the journal Nature.

QS-21 is one of the strongest vaccine adjuvants, and is traditionally extracted from the Chilean soap bark plant – yet the extraction uses caustic and toxic chemicals and it is so difficult to produce that it costs several hundred million dollars per kilogram (2.2 pounds). According to Keasling, the production of QS-21 involved the insertion of 38 different genes from six organisms into yeast – building one of the longest biosynthetic pathways ever transplanted. Currently, a liter of the fermenting bioengineered yeast can produce about 100 micrograms of QS-21 in three days, with a market value of about $200. But yeast biosynthesis is scalable.

Credit: Bianca Susara/Berkeley Lab

“My whole thing is, I want to make everything from a single sugar. I just want to feed yeast glucose, because eventually we want this process to be scaled. And if you feed them a bunch of fancy intermediates, then it’s going to result in a process that is not scalable,” Keasling said. “In the end, I’d like to start with glucose, so when the production is performed in large tanks, they’re able to produce QS-21 as easily and inexpensively as possible.”