Researchers at the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU), the Joint BioEnergy Institute (JBEI), and the Engineering Division’s Engineering Small Project Support (EsPS) team collaborated on the development of a custom chemical reactor that will help bridge a critical gap in testing new chemistry processes before upscaling them to larger experiments.

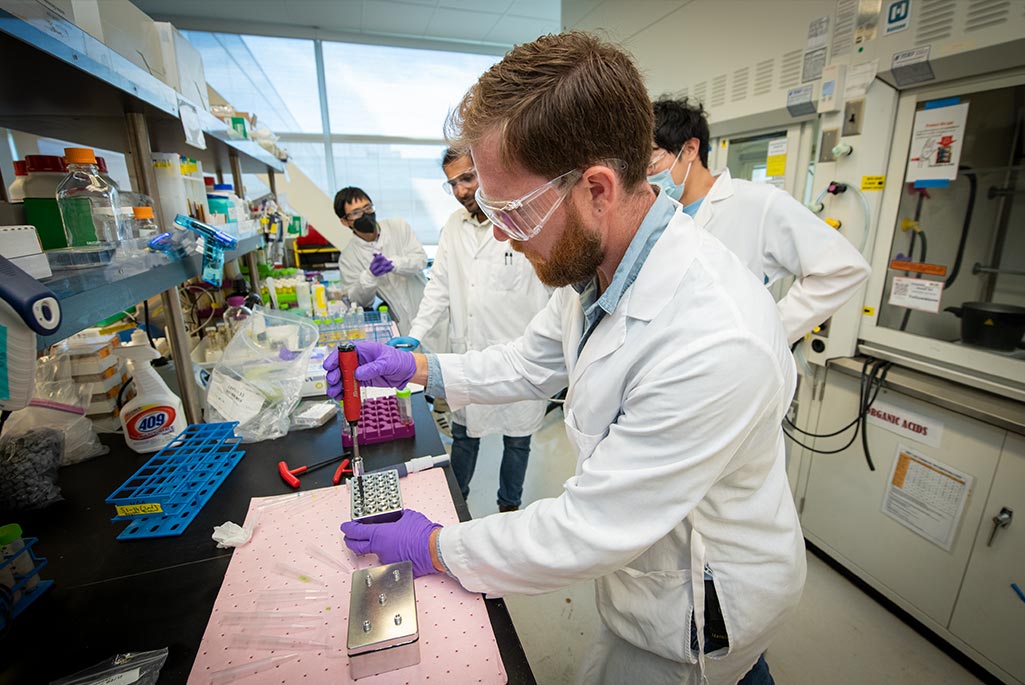

ABPDU team members Chang Dou and Ning Sun, along with Hemant Choudhary, an affiliate scientist at JBEI, were looking to develop a small-scale high-throughput chemical reactor, an enclosed vessel that allows experimenters to quickly test an array of chemical reactions at high temperature and high pressure. Mechanical Engineer Nick Wenner stepped in to provide support courtesy of EsPS.

“We were looking for something that will allow us to rapidly test new chemistries at a small scale but with high throughput,” said Dou, a senior scientific engineering associate in the Biological Systems and Engineering (BSE) Division. “Instead of doing one, two, or a couple tests at a time, we wanted to be able to do dozens or hundreds at a time.”

In addition, the team needed a vessel that could maintain high pressure, withstand a range of chemicals, and permit the ability to actively stir the materials inside each well.

“All of these elements are essential to ensure that our small-scale reactions meaningfully inform larger-scale operations, since the same factors are present in full-scale reactors. This is essentially the science of scaling-up, which is the central theme of our research at ABPDU,” said Ning Sun, BSE staff scientist.

The team was unable to find any off-the-shelf product that met their experimental requirements.

“At ABPDU and JBEI, they have a serial process of steps up in scale for chemical reactions that require high pressure. They have three small reactors with, say, a liter in capacity, and then they have two 10-liter reactors, one 50-liter reactor, and finally a 200-liter reactor,” explained Wenner. “And they’re working with partners to help make the leap from the bench top to a commercial product or process.”

To help plug this gap in ABPDU’s and JBEI’s scaling processes, the EsPS team developed a new small-batch reactor made of a base constructed of 316L stainless steel, a material chosen for its affordability, machinability, and chemical compatibility with the intended testing materials. It was designed to match the dimensions of a standard 24-well plate to facilitate compatibility with other systems used for well plates, such as solid and liquid handling systems and heating and stirring systems. The device has continued to evolve alongside the needs of the ABPDU team.

“We use the small-batch reactor for high-temperature, high-pressure reactions, including both lignocellulosic biomass conversion and plastics depolymerization for further upgrading,” said Sun. “The reactor has been used in multiple DOE-, DoD-, and industry-funded projects, including the research collaboration with JBEI, BioCircular Valley, and X, the moonshot factory. It has contributed to multiple milestones and deliverables.”