Commercially manufactured hydroxyapatite is used in surgery and dentistry to repair bones and teeth when they’re broken. Now a team from the Lawrence Berkeley National Laboratory (Berkeley Lab), UC Irvine, and the University of Illinois Urbana-Champaign (UIUC) genetically modified yeast to produce the same material. The lightweight material’s remarkable strength and toughness make it an excellent candidate building material and even as a replacement for some types of plastic.

Their work, recently published in Nature Communications, not only provides a cost-efficient pathway to produce hydroxyapatite, but also a practical mechanism for reducing the cost of wastewater treatment, an energy efficient means of producing fertilizer, and opens the door for other yeast-based technologies that can create useful materials out of scavenged minerals.

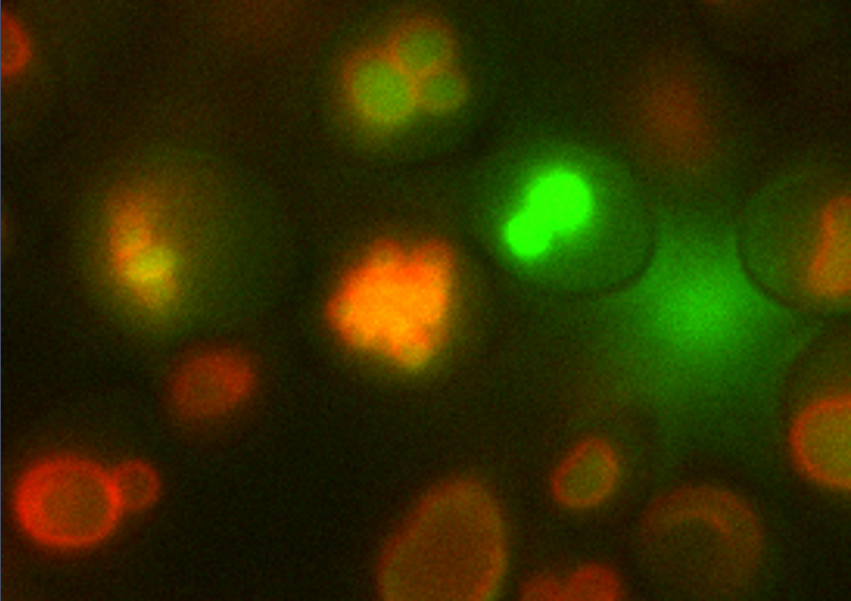

The star of the show is the team’s strain of Saccharomyces boulardii, a yeast closely related to the species used to brew beer and make bread. S. boulardii likes to grab minerals from its environment and store them inside a special membrane compartment. Co-authors Yasuo Yoshikuni, head of the DNA Synthesis Science Program at the Joint Genome Institute (JGI), and Peter Ercius, staff scientist at the National Center for Electron Microscopy at the Molecular Foundry, were exploring ways to make functional biomaterials with microbes when they realized that S. boulardii was naturally performing activities similar to osteoblasts, the specialized animal cells that make hydroxyapatite and form bone. Both the JGI and the Molecular Foundry are DOE Office of Science user facilities located at Berkeley Lab.

“The serendipitous part is this yeast already had similar molecular mechanisms,” said Yoshikuni, who specializes in engineering microbes to produce fuels, chemicals, and materials at the JGI. “Just mild tweaking was sufficient to convert the yeast into a cell factory for hydroxyapatite.”

This article has been adapted from the Berkeley Lab News Center.